2550o C Sintering Furnace

Maximum Temperature: 2550o C

Graphite Hot Zone Dimensions: 21.5” wide x 13.625” high x 42” deep

Element Dimensions: 17.5” wide x 12.25” high x 40” deep element-to-element

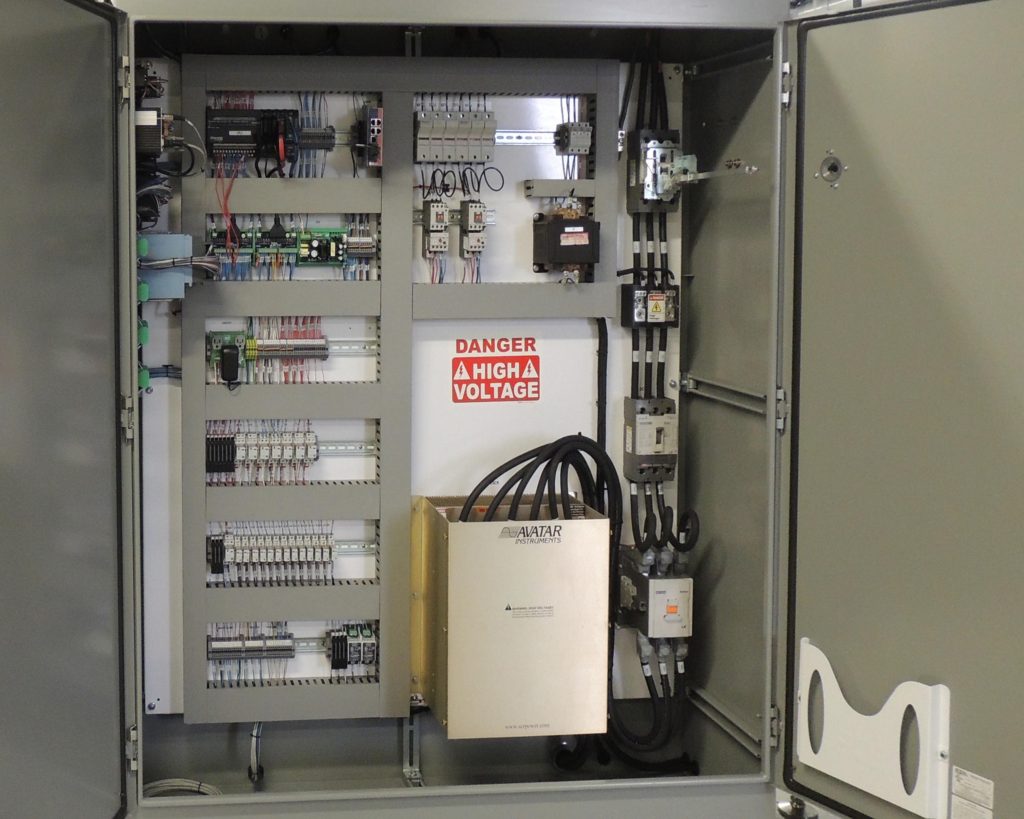

Power Supply: 480 volts, 3 phase, 230 AFL

Atmosphere: Rough vacuum operation / Atmosphere operation

Features:

- Standard one-year warranty.

- This is a compact, packaged, and assembled unit that is shipped as one piece, requiring only the water, gas, and power to be connected to the appropriate locations.

- Suitable for sintering silicon carbide.

- Yokogawa UP550 digital programmable temperature controller with 30 programs and 300 segments.

- Fully automatic operation with PLC programmer/controller for fully automatic operation with alphanumeric display to indicate furnace processing cycles.

- Graphite heating elements on the left and right sides.

- Hot zone will have grafoil on all internal surfaces (left, right, top, bottom, front, and back). There will be 4” of rigid graphite insulation. The bottom internal insulation face will have a layer of 1/8” carbon/carbon fiber.

- Top-mounted gas injector tube with graphite tubes to enable a more positive connection to the work box with the rear door open.

- Stokes 149 piston pump with Edwards EH250 Roots blower.

- Thermocouple retractor system with optical pyrometer.

- Optical site port for the pyrometer with an open-end target tube in the side of the furnace.

- MKS digital vacuum gauge.

- Digital high limit safety controller with Type “C” thermocouple inserted approximately halfway into the graphite hot zone insulation.

- Oil bubbler on the exhaust to minimize air backstreaming to facilitate longer hot zone and element life.

- We provide written operating procedures, complete detailed electrical schematics, and manuals for all instrumentation and controls on the furnace.