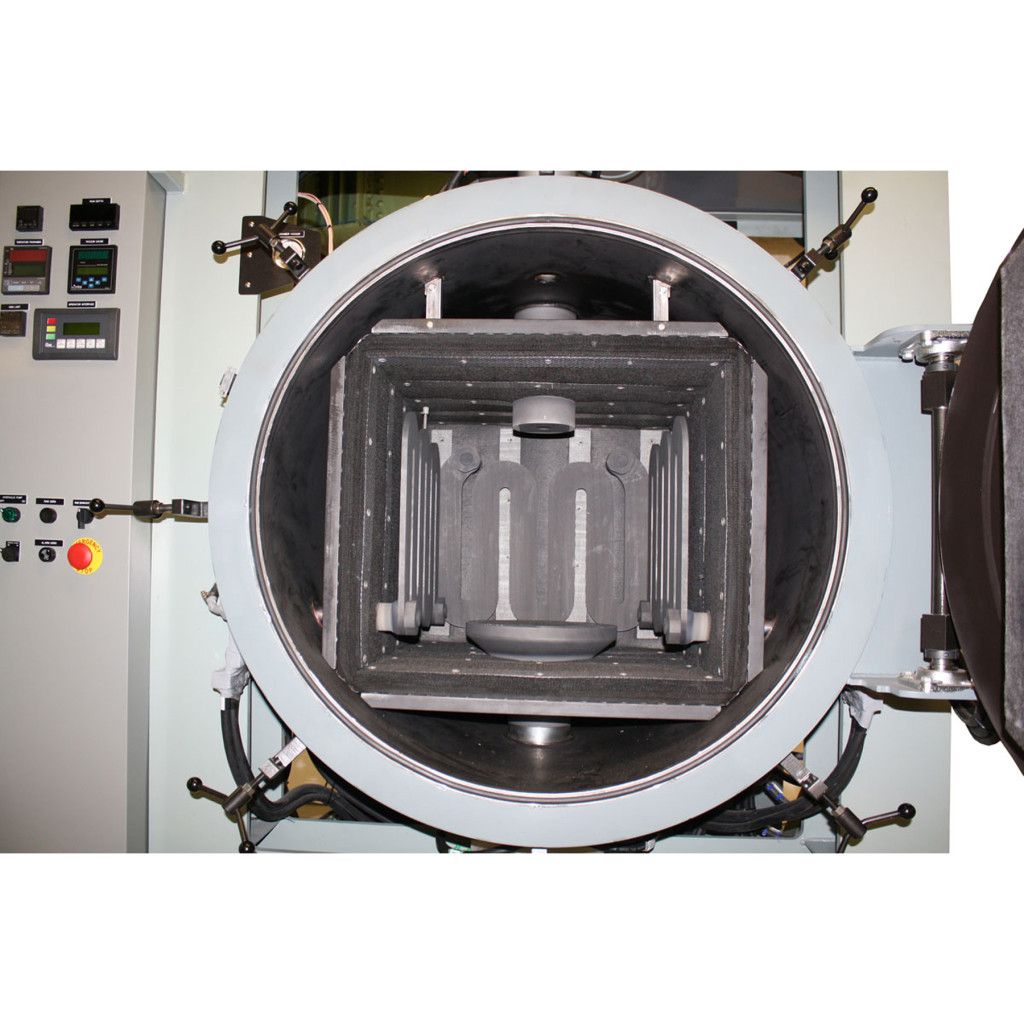

50-Ton Vacuum Hot Press (445-Kilonewton)

Maximum Temperature:

- 2000o C (3632o F) – Optional 2200o C Operation (3992o F)

Power Requirements:

- 480 volts, 60 hertz, 3 phase (Optional 380 volt, 50 hertz operation available for additional charge)

External Dimensions:

- 99” high x 74” wide x 74” deep (251cm x 188cm x 188cm)

Atmosphere:

- High vacuum, rough vacuum, and atmosphere operation

Features:

- Standard one-year warranty.

- This is a compact, packaged, and assembled unit.

- Graphite hot zone and four-sided graphite heating elements for optimum uniformity.

- Upper ram is moveable with 6” stroke. Bottom ram is fixed.

- Fully automatic operation with PLC programmer/controller with alphanumeric display to indicate hot press processing cycles.

- Programmable closed-loop temperature/pressure control. This system will consist of a Yokogawa UP750 two-loop programmable temperature controller with 300 programs and 3,000 segments. The UP750 will control the temperature and the pressure on the hydraulic ram on the same timeline.

- Mechanical vacuum pump.

- High vacuum operation. Includes 6” high-speed diffusion pump, high-vacuum gate valve, foreline valve, and all necessary vacuum plumbing and automation to enable the system to operate in high vacuum.

- Liquid nitrogen cold trap with digital temperature controller to minimize liquid nitrogen consumption.

- Digital ram movement indicator with resolution to the nearest .001”.

- Digital vacuum gauge with a range of atmosphere to 1 x 10(-5) Torr.

- Digital high-limit safety controller with Type “C” thermocouple.

- We provide written operating procedures, complete detailed electrical schematics, and manuals for all instrumentation and controls on the hot press.

- Includes one day of test fire and operator training at our plant in Terryville, Connecticut, USA.

Options:

- 2200o C operation (3992o F). Includes automatic thermocouple retractor and optical pyrometer.

- Roots blower.

- Remote diagnostics via a modem, enabling us to remotely aid in troubleshooting the hot press and guide your maintenance people directly. This should virtually eliminate the need for field service.

- 6-channel Yokogawa paperless datalogging chart recorder with digital communications. Network compatible – can appear as a node on a network, making remote data gathering fast and easy. Includes built-in memory card for storage.

- Yokogawa Light Loader to facilitate uploading and downloading programs, configuration files, and auto-tuning parameters. This device clips on the face of the Yokogawa UP750 instrument and plugs into a USB port on a PC-based laptop or desktop computer, greatly facilitating and simplifying instrument configuration, program storage, and auto-tuning. Can be used for writing programs and storing detailed configuration data.