Maximum Temperature:

- 1300o C (2372o F)

Maximum Load Size:

- Up to 1500 pounds (680 kilograms)

Power Requirements:

- 480 volts, 3 phase, 60 hertz

Atmosphere:

- Capable of either partial pressure operation or full atmosphere inert gas operation, using the combination of heating elements and a convection fan in the unit to heat the tubes in an efficient and uniform manner. Convection fan limited to 500o C operation (932o F).

- After initial pump down and backfill, full atmosphere inert gas operation.

- Capable of heating at the rate of 3.5o per minute to 5o per minute.

- Partial pressure operation with nitrogen or argon at approximately 1.2 to 1.3 Torr, up to a maximum of 10 Torr.

- Rough vacuum operation with mechanical vacuum pump and Roots blower.

- Optional one-bar recirculating gas quench cooling.

Features:

- Standard one-year warranty

- This is a totally enclosed, packaged, and assembled unit that is shipped as one piece, requiring only the water, gas, and power to be connected to the appropriate locations.

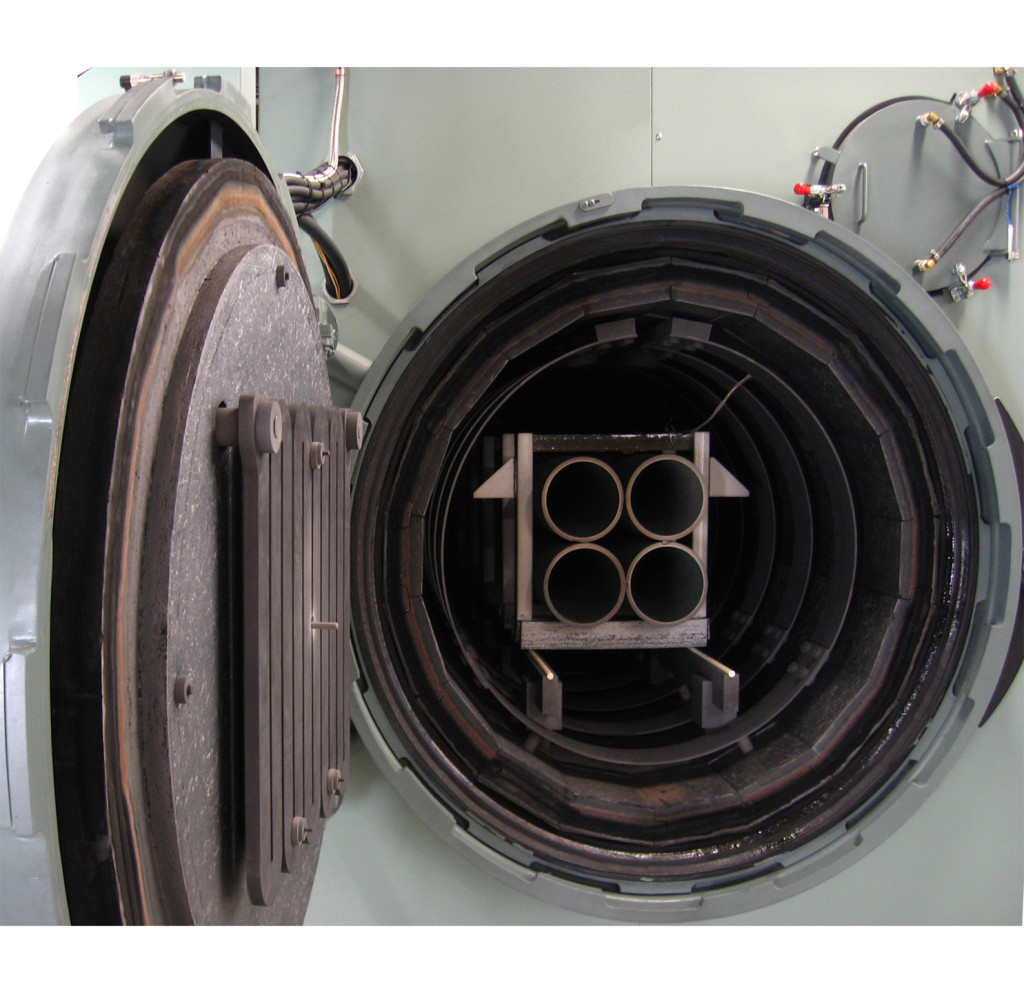

- Designed to simultaneously process up to four tubes measuring 7.5” diameter x 8.5’ long (19cm x 259 cm).

- Yokogawa controller/recorder.

- Cascade control, which consists of the programmable temperature controller controlling the work thermocouple as the “master” and an additional “slave” controller controlling the heating elements. The “slave” controller is slaved to the “master” controller. As the temperature setpoint is approached, the gradient is reduced automatically. This feature is critical to consistent low temperature response and eliminates overshoot at the high temperature setpoint.

- PLC programmer/controller for fully automatic operation with alphanumeric display to indicate furnace processing cycles.

- Mechanical vacuum pump.

- Roots blower.

- Cold trap to collect binders.

- The temperature controller will program cool the furnace using the natural cooling rate of the furnace from approximately 1200o C (2192o F) to approximately 700oC (1292o F), at which point the optional recirculating gas quench can backfill and rapidly cool the work.

- Graphite hot zone.

- Graphite heating elements 360o around the work for optimum temperature uniformity.

- Front and rear trim heaters slaved to the center control zone for optimum temperature uniformity.

- High limit controller.

- Digital vacuum gauge.

- We provide written operating procedures, complete detailed electrical schematics, and manuals for all instrumentation and controls on the furnace.

- Includes one day of test fire and training at our plant in Terryville, Connecticut, USA.

Options:

- Remote diagnostics via a modem, enabling us to remotely aid in troubleshooting the furnace and guide your maintenance people directly. This should virtually eliminate the need for field service.

- Mass flow control of the primary flow gas through the furnace.

- One-bar recirculating gas quench for rapid cooling.

- 12-position vacuum-tight thermocouple port.

- Work truck to load and unload the required fixturing to hold the tubes.